Can You Make Butcher Block Island Top Different Colors

Before this week I shared how I built thiskitchen islandfor my mom. As promised, today I'm going to show you how I built the butcher block tabular array height for it. I went dorsum and forth, fretting over whether to build a butcher block table meridian or to buy one. When I say buy one, I mean my mom. She purchased all of the materials. I was the skilled "fly past the seat of my pants" labor. I searched high and low for a cheap butcher block countertop that would fit the specifications I needed, but they were crazy expensive! I thought almost doing wide planks, but my husband warned me that they might warp after a while and that small planks were best. It wasn't until I saw thistutorialonSawdust and Embryosthat it finally clicked.

The well-nigh common wood in butcher blocks is maple because of its hardness. I had planned to use maple, but when I went to my localWoodworkers Source,I happened to see the knotty alder. It is a little softer than difficult maple, but still a hard wood and when I discussed information technology with one of the employees, nosotros both agreed information technology would be a fine choice for the island peak. The best part is that it was half the price! I chose my boards and had another employee plane and rip the boards down into manageable sticks for me.

My forest was planed at one 3/four″ thickness and I had information technology ripped into 1 1/2″ sticks. When I got domicile, I cut all of my long sticks into smaller pieces. I had to cutting out some knots (they don't call it knotty alder for nothing), but that gave me the random patterns I was looking for. I turned the woods pieces on their sides so my slats were i i/2″ thick and 1 three/4″ broad.

I got all of my clamps lined upward and went to work. I used Titebond III to glue the pieces together. It is nutrient safe, and so a good choice for something like this. I turned the boards to the side I wanted to gum and started laying information technology on. I don't know if it was the high 80s temps, only the mucilage formed a skin pretty fast on me, so I would work in two rows at a time and then stick them together. Squeezing a bead of glue and then using a foam roller to spread it out works actually well. Be sure that if you lot have short pieces to gum those ends together likewise.

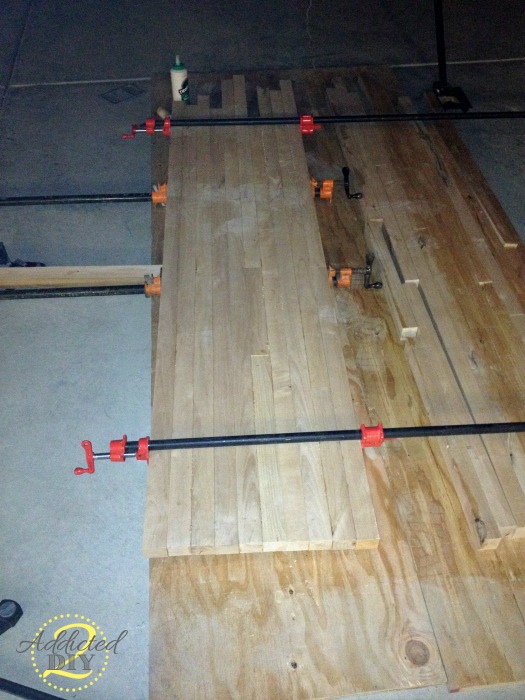

When sticking the pieces of forest together, employ a mallet to pound whatsoever shorter pieces into a tight joint. Then clamp tightly using clamps on the bottom as well as the top. This prevents the glued pieces from bowing, which nobody wants. I only glued one-half on the first night. It was getting dark and I wanted to get dinner started before my husband came dorsum from soccer practice with the boys.

On the 2nd dark, I finished putting all of my pieces together and enlisted every long clamp we had in our garage to make sure those joints were tight. Y'all'll accept to forgive me for the bad night time pics. My time to work on things is either while my boys are in school or while they're in bed.

I let information technology set for 24 hours and then took it back to the wood shop and had them finish it off for me. They cutting information technology downwards to size, squared up the ends, and so sanded it smoothen for me. When all was said and done at the wood shop, the tabletop when from approx 1 1/2″ thick to a picayune over i 1/4″ thick. When I got the table top back home, I used my orbital sander to round the edges and sand it completely smooth with 220 grit sandpaper.

I used butcher cake conditioner on both sides of the butcher block. This is the lesser side. You lot tin meet that the conditioner really brought out the warm hues of the alder.

It turned out then much better than I had imagined it would. To be perfectly honest, I was freaking out when I was gluing information technology all together. I was afraid information technology would have a lot of gaps or that it would just autumn apart on me. Truth be told, there are a couple of tiny gaps where the ends didn't join perfectly together. The good news was that several websites I looked at said to use a mixture of beeswax and mineral oil to fill those gaps. Gauge what the butcher block conditioner is made of? I merely made sure to take extra intendance to put more of the conditioner in those niggling gaps.

If you are looking to save a little coin on your project, or if you are like me and you sometimes experience like information technology'southward not DIY unless EVERYTHING is done yourself, I hope you lot will find this tutorial helpful. If you lot have leftover wood similar I do, you can also make some cutting boards with it. I'one thousand thinking those would be fun Christmas presents.

I seriously love to hear your comments, so please permit me know what you think! Also, sharing with friends, liking, pinning, and tweeting is ever welcome!

~Katie

This post contains some chapter links for your convenience. Please click to read my full disclosure policy.

dasilvaplimparthid.blogspot.com

Source: https://addicted2diy.com/how-to-build-your-own-butcher-block/

0 Response to "Can You Make Butcher Block Island Top Different Colors"

Post a Comment